Hydroponic Green Forage in Diets of Growing Pigs

In this experiment, it is concluded that the inclusion of 30% hydroponic fodder in the diet of growing pigs improves their productive behaviour.

Hydroponic Green Forage in Diets of Growing Pigs

Pedro Cisneros Saguilán

Herminio Aniano Aguirre

Ricardo Martínez-Martínez

Armando Gómez Vázquez

María de los Ángeles Maldonado Peralta

Marco Antonio Ayala Monter

National Technology of Mexico-Technological Institute of Pinotepa. Av. Tecnológica S/N, Col. Dispensario, Pinotepa Nacional, Oaxaca, Mexico. CP. 71600.

University of Guadalajara-University Center of the South Coast Autlán de Navarro. 151 National Independence Avenue, Centro, Jalisco, Mexico. CP. 48900.

Academic Division of Agricultural Sciences – Autonomous Juárez University of Tabasco. Villahermosa-Teapa highway km 25, Teapa, Tabasco, Mexico. CP. 86280.

Faculty of Veterinary Medicine and Animal Husbandry no. 2-Autonomous University of Guerrero. Acapulco-Pinotepa National Highway km 197.

Cuajinicuilapa, Guerrero, Mexico. CP. 41940.

Abstract

The importance of conducting studies on the use of hydroponic green corn fodder (HGCF) is because, the productive and economic impact on the feeding of pigs in the region of the Coast of Oaxaca has been poorly evaluated. The objective of the study was to evaluate the productive behaviour in growing pigs with HGF as a supplement, with diets based on commercial feed and including HGCF. The research was conducted during the months of August to November 2017. Four treatments were evaluated [T1: control, T2: 85/15%; T3: 70/30% and T4: 55/45% of food trade and HGCF respectively], under a completely randomized design with four repetitions per treatment. 16 dewormed and vaccinated pigs were used, with an initial weight of 10.41 kg. Total feed consumption (TFC), feed conversion (FC), total weight gain (TWG), and cost-benefit ratio (CBR) were evaluated. The data obtained were analysed by Proc. SAS GLM. The averages were compared with the Tukey test. Differences (p˂ 0.05) were found in the TFC, where the highest value was 110 kg. The highest TWG was 42.67 kg. As for CBR, the productive parameters are improved as the HGCF percentage increases (45%) In the diet of pigs. It is concluded that the inclusion of 30% of HGCF in the diet of growing pigs improves their productive behaviour.

Pig farming is a livestock activity that has increased worldwide in recent years, with China being the main producer of pork. In Mexico, one of the problems that pig producers have is the high cost of feeding, ranging from 60 to 70% of their livestock production system.

However, pig farming tends to increase in the coming years, as per capita consumption has increased more than 12.8 kg (SIAP, 2015). In the particular case of the state of Oaxaca this problem is not the exception; however, an advantage that it has is its participation at a national level of 4% in meat production, which makes pig farming an attractive activity for producers in the region (Torres-Novoa and Hurtado-Nery, 2007).

However, the high feed costs mean that most pork producers are limited to carry out this livestock activity. Therefore, an alternative to reduce production costs is the use of new alternatives, such as the use of hydroponic green forage (HGF) in pig feed (Müller et al., 2005; Herrera et al., 2007 ), since it has been mentioned that with this technology the production cost is reduced and a harmless meat is obtained (Osorto et al., 2007; Romero, 2009).

The production of HGF consists of germinating grass or legume seeds such as oats, corn, wheat, alfalfa, among others, until seedling growth, under conditions of light, humidity and temperature suitable for each crop species (Albert et al., 2016). Unlike the conventional grazing-based feeding system, the HGF represents an alternative animal feeding, where the leaves, stems and roots are used; that is, the complete plant (Ramírez and Soto, 2017).

Making use of hydroponic green forages has several advantages, one of the advantages of using HGF is that it can be produced throughout the year and in small areas of soil or in trays using straws, husks of grass grains, coconut fiber, tezontle, etc., as a substrate, using a controlled irrigation system, where the necessary water is supplied with the essential nutrients for each crop (Rodríguez et al., 2009).

Another advantage is the short forage production time, since in a period of 15 to 20 days forage can be available for animal feed and in this case for pigs (FAO, 2001). Among the most used grasses as HGF is corn (Zea mays L.), since it presents high forage yields ranging from 3 91 to 4 64 kg m-2 and the dry matter content of 25.5 and 19.24% at 10 and 12 days, respectively (Albert et al., 2016; Naik et al., 2012; García-Carrillo et al., 2013).

In the coast of Oaxaca region, there are no studies or the use of hydroponic green corn fodder (HGCF) in the diet for the production of pork is not well documented, as well as the cost-benefit of this alternative food. Therefore, the objective of the present study was to evaluate growing pigs, diets based on commercial feed and with the inclusion of hydroponic green maize forage, where total feed intake (TFC), feed conversion (FC), weight gain (TWG) and calculate the cost-benefit ratio (CBR).

Study Area Description

The research was carried out during the months of August to November 2017, at the facilities of the Technological Institute of Pinotepa, Experimental Unit ‘San José Estancia Grande’ of the Department of Agricultural Sciences, located in the municipality of San José Estancia Grande, Oaxaca, km 26.5 of the Pinotepa National Highway, Oaxaca-Acapulco, Guerrero, at 16° 22’ north latitude and 98° 13’ west longitude (García, 2004).

The climate in this region is warm sub-humid with rains in summer, with an average annual temperature and precipitation of 26.9 °C and 800 mm, respectively and at 70 masl (García, 2004).

Treatment and Experimental Design

The treatments evaluated were: T1 (control): 100% commercial balanced feed, T2: 85% commercial balanced feed + 15% HGCF; T3: 70% commercial balanced feed + 30% HGCF and T4: 55% commercial balanced feed + 45% HGCF. A completely randomized design was used, with four repetitions per treatment, where the experimental unit consisted of one pig, giving a total of 16 pigs.

Variables Evaluated

The total food consumption (TFC) expressed in kilograms was evaluated, it was calculated by subtracting the food not consumed from the food offered during the day. The total weight gain (GTP) of the pigs was obtained by the difference between the final weight and the initial weight. The feed conversion (FC) was obtained by dividing the total consumption by the increase in live weight of each animal. While the cost-benefit ratio (CBR) was obtained by dividing the income from the sale of the GTP in the local market, by the costs of the food consumed during the production cycle.

Experiment Development

The study lasted 12 weeks. Sixteen weaned pigs of the Landrace breed were weaned with an average initial weight of 10.41 kg and an approximate age of three months. Prior to the start of the experiment, they were administered vitamins and antiparasitic against endoparasites and ectoparasites.

The pigs were housed in individual pens provided with feeders and troughs with ad libitum water, where they had an adaptation period of 10 days, providing the pigs with the proposed diets for commercial feed and HGCF in the respective feeders in a restricted manner and the consumption according to what they left daily in the feeders.

The diets used were based on the commercial balanced feed of the Api-Aba Premium line, for the growth-fattening stage. The HGF used in the present study was produced at the same Technological Institute, using a local variety of corn seeds, with a yield of 3.5 kg of HGCF per 600 g of corn

Statistical Analysis

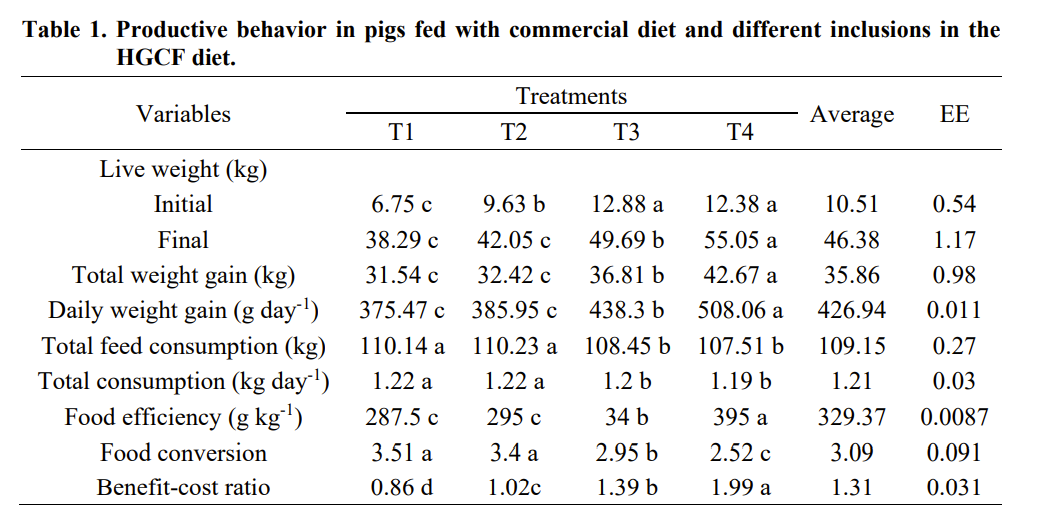

The data obtained from the evaluated variables were subjected to an analysis of variance using the GLM procedure of the SAS program (2002). Tukey’s test was used for comparisons between treatments, with a significance of 0.05. Total weight gain Statistical differences were found between treatments (p˂ 0.05) for the variable total weight gain (Table 1), where the highest value (42.67 kg) was obtained with treatment T4, a value that was different and higher (p˂ 0.05) to that registered with the T3 treatment, with an average of 35.81 kg. These results are different from those reported by Cunuhay (2013), who found that the highest total weight gain was obtained in pigs with 100% commercial balanced feed, reaching a final weight gain of 46.4 kg and less weight gain when 45% of HGCF was included in the diet with a weight gain of 36.3 kg.

In Figure 1, the behavior in the total weight gain per week of the pigs fed with diets based on commercial feed and different percentages of inclusion of hydroponic green forage from corn is shown. Weight gain in pigs on an HGF-based diet improves by offering them ‘ad libitum’. In this study, as the HGF was increased, weight gain was improved, making it a feeding alternative for pigs.

It is also known that the HGF provides the pig with proteins, minerals and vitamins which are more assimilable to the animal as they are soluble, which is not the case with dry grain. Vitamins are of great importance in the fertility and productivity of animals, which is reflected in the weight gain of pigs

Among the first studies done in this regard (Sánchez and Escalante, 1998) reported better weight gain in pigs fed on HGF. And this research confirms this by adding different levels of HGCF to the diet.

Total Food Consumption

Statistical differences were found for the TFC variable (p˂ 0.05), where the highest consumption (110.23 kg) was obtained in treatment T2, a value that was similar (p˃ 0.05) to that obtained with T1 (110.14 kg), but different and greater than (p˂ 0.05) to the values obtained with the T3 and T4 treatments. Similar results to those found in the present study were reported by Cunuhay (2013).

Who found that the total average food consumption registered significant statistical differences, where the highest consumption occurred with diets where 100% of food was commercially balanced (131.34 kg), with total average food consumption of 2.34 kg animal-1 day-1.

While the lowest total food consumption was found in T3 containing 45% of HGCF in the diet, the registered consumption was 1.72 kg animal-1 day-1. This technology of producing HGF is complementary and not competitive with that used in conventional forage production, making it a good alternative for feeding animals such as cattle, goats, sheep, equines, birds and pigs.

In this study where it was observed that pigs consume forage very well and useful in periods of forage shortages. The supplementation of hydroponic green corn fodder in the pig ration is a technological alternative for feeding pigs, which is why the consumption of this HGF is not a limitation for pigs since they accept it and consume it for good forage palatability (Naik et al., 2015).

Food Conversion

Currently, the fattening pig feeding system requires that they have good feed conversion; that is, if we say that a pig gives a feed conversion of 2, it indicates that for each pound or kilogram of live weight it gained, its consumption was 2 kg of feed. In this regard, there are few studies and in this investigation a significant difference (p> 0.05) was found in terms of AC, where the best conversion was from T1 and T2, while the lowest AC was found by T4 and T3 (Table 1).

The results found in this investigation coincide with the data obtained by Cunuhay (2013), who found that the best dietary conversion is when 45% of HGF is added to the diet with 2.67. Coincides with what was found by Adebiyi et al. (2018), who observed that in pigs weaned and fed with HGF the feed conversion was improved.

Cost Benefit Relation

In this study, the RBC ratio was better when the inclusion percentage of HGCF was increased in the diets of growing pigs and under the environmental conditions already described in the methodology (Table 1). This may be due to the low cost of HGCF production due to the fact that local seeds were used and its high yield, since 600 g of corn produced 3.5 kg of HGF; therefore, a higher level of substitution of HGCF in the pig’s diet substantially improves CBR.

The above is in agreement with the literature Arriaga-Jordan et al. (2002), documented that feeding HGCF reduces production costs in feeding pigs as long as hydroponic forage occurs. Therefore, the lowest profitability is found when the diet is 100% commercial food this is logical due to the high cost of inputs.

Another advantage is that by including more than 15% of HGCF in the pig diet, weight gain is favoured and it also has a positive impact on profitability. The results found agree with those of Romero (2009), who mentions that the diet with the best CBR was when more than 40% of HGF is included.

Conclusions

The inclusion of hydroponic green forage from corn in feed diets of fattening pigs in this study demonstrated significant results; since, as the percentage of HGCF increased in the evaluated treatments, it was reflected in the reduction in consumption of these, the daily and total weight gain increased, as well as the food conversion and the cost benefit ratio in the treatments whose HGCF content was higher. The use of 55% of commercial balanced feed and 45% of hydroponic green

forage from corn is recommended.

Cited Literature

Adebiyi O. A.; Adeola, A. T.; Osinowo, O. A.; Brown, D and NG’Ambi, J.W. 2018. Effects of feeding hydroponics maize fodder on performance and nutrient digestibility of weaned pigs. Appl. Ecol. Environ. Res. 16(3):2415-2422.

Albert, G.; Alonso, N.; Cabrera, A.; Rojas, L. y Rosthoj, S. 2016. Evaluación productiva del forraje verde hidropónico de maíz, avena y trigo. Compendio de Ciencias Veterinarias. 6(1):7-10.

Arriaga, C. M.; Albarrán, B.; Espinoza, A.; García, A. and Castelán, O. A. 2002. On-farm comparison of feeding strategies based on forages for small-scale dairy production systems in the highlands of central México. Expl Agric. 38(1):375-388.

Cunuhay, P. O. R. 2013. Niveles de forraje verde hidropónico de maíz en la dieta alimenticia enengorde de cerdos mestizos en el cantón Maná. Tesis. Universidad Técnica de Cotopaxi. 192 p.

FAO. 2001. Organización de las Naciones Unidas para la Agricultura y la Alimentación. Oficina Regional de la FAO para América Latina. Manual técnico: forraje verde hidropónico. Santiago, Chile. 68 p.

García, E. 2004. Modificaciones al sistema de clasificación climática de Köppen. Universidad Nacional Autónoma de México, Instituto de Geografía. México. 91 p.

García-Carrillo.; Salas-Pérez.; Esparza-Rivera.; Preciado-Rangel y Romero-Paredes. 2013. Producción y calidad fisicoquímica de leche de cabras suplementadas con forraje verde hidropónico de maíz. Agron. Mesoam. 24(1):169-176.

Herrera, A. A.; De Pablos, A. L A.; Maduro, R. L.; Benezra, S. M A. y Ríos, de A. 2007. Degradabilidad y digestibilidad de la materia seca del forraje hidropónico de maíz (zea mays). Respuesta animal en términos de consumo y ganancia de peso. Rev. Científ. FCVLUZ. 17(4):372-379.

Müller, L. M. P. A.; Santos, O.S.; Sandro, L. P.; Medeiros, V. H.; Durval, D. N.; Evandro, B. F. and Bandeira, A. H. 2005. Growth and bromatologic composition of hydroponic corn fodder in differents dates of harvest and sowing densities. Zootecnia Tropical. 23(2):105-119.

Naik, P. K.; Swain, B. K. and Singh, N. P. 2015. Production and utilization of hydroponics fodder. Indian J. Animal Nutr. 32(1):1-9.

Naik, P. K.; Dhuri, R. B.; Swain, B. K. and Singh, N. P. 2012. Nutrient changes with the growth of hydroponics fodder maize. Indian J. Animal Nutr. 29(2):161-163.

Osorto, W. A.; Lara, P. E.; Magaña, M. A.; Sierra, A. C. y Sanginés, J. R. 2007. Morera (Morus alba) fresca o en forma de harina en la alimentación de cerdos en crecimiento y engorde. Rev. Cubana Cienc. Agríc. 41(1):61-65.

Ramírez, V. C y Soto, B. F. 2017. Efecto de la nutrición mineral sobre la producción de forraje verde hidropónico de maíz. Agron. Costarric. 41(2):79-91.

Rodríguez, R. G.; Hernández-Acosta, D. L.; Flores-Sáenz, I. C.; Quintero-Ramos, A.; SantanaRodríguez, V. y Rodríguez-Rodríguez, S. M. 2009. Cascarilla de avena y paja de trigo utilizados como sustrato para la producción de forraje verde hidropónico. Tecnociencia

Chihuahua. 3(3):160-185.

Romero. 2009. Evaluación de dos niveles de reemplazo de ingredientes en dietas tradicionales por forraje hidropónico de maíz para cerdos confinados en la fase de crecimiento y acabado,Escuela Superior Politécnica del Litoral. 146 p.

Sánchez, del C. F. y Escalante R. 1988. Hidroponia. 3ª. edición. PATUACH. Universidad Autónoma Chapingo. Chapingo, México. 194 p.

SAS. 2002. Statistical Analysis Sistem. SAS Proceeding Guide, Version 9.0 SAS Institute. Cary NC. USA.

SIAP. 2015. Sistema de Información Agroalimentaria y Pesca. Producción Ganadera. Información estadística de la producción ganadera nacional y pecuaria. https://www.gob.mx/siap/acciones-y-programas/produccion-pecuaria.

Torres-Novoa y Hurtado-Nery. 2007. Análisis de parámetros de desempeño zootécnico en la fase de cría en una porcícola comercial del departamento del Meta. Orinoquia. 11(12):59-65.

Want to know more?

As one of the world’s leading manufacturers of vertical farming technology, we’d love to empower you to grow food for your community.